The concept of design-freeze in product development was one which I was taught at an early stage of my career. It is the point at which Design Release Engineers down their virtual CAD pens and upload final designs to the company Product Lifecycle Management (PLM) system.

This freeze is considered essential to allow all designs to be released to part suppliers, tooling vendors and equipment integrators to fabricate all the elements of the manufacturing system and bring them together in a coordinated manner to produce a complete car, plane, rocket, etc.

🏗️ A Rigid Process

Prior to the advent of gigacastings, a car body structure typically consisted of 400–500 individual sheet metal panels, assembled by a comparable number of robots.

To coordinate the complex set of activities required to assemble these hundreds of interdependent components into a robust final product, legacy automakers have long relied on their own proprietary versions of a tightly controlled Stage-Gate process.

In this process, the product design advances through a series of predefined milestones, or stage-gates (shown as the red diamonds in Figure 1). These gates mark progress from initial market positioning, through concept development and detailed design, followed by testing & validation, prototype manufacturing, and finally into full-scale volume production.

Each milestone comes with a defined list of deliverables, rigorously assessed in the often-dreaded stage-gate review, where a go/no-go decision will be made on whether to progress the vehicle program through to the next development stage.

As the product design makes its way through each stage gate it steadily grows in maturity, until it reaches Concept Confirmation. At this point, the vehicle is considered fully defined digitally.

Figure 1: Magna Product Development V-Model: https://www.magna.com/stories/inside-automotive/concept-creation/new-car-development-process.

📐 The V-Model

The increasing level of detail is structured using the V-model, where the design cascades down the left-hand side of the diagram, shown in Figure 1, from customer level to the point where every individual component has its own full set of specifications at the bottom of the ‘V’.

Between Concept Confirmation and Functional Confirmation, the design is validated using a range of digital simulations and physical models. Virtual tools include Computer Aided Engineering (CAE) to assess crash performance. Virtual Engineering (VE) to simulate the manufacturing process and Dimensional Variation Analysis (DVA) to model assembly tolerances as they stack through the manufacturing process.

Physical tools are used to complement virtual validation, with the fabrication of models such as the ‘Function Cube’, shown in Figure 2. This is a CNC machined exterior and interior model representing the visible surfaces of the CAD engineered product.

This model serves to validate the digital geometry before tooling kick-off and provides an opportunity to assess the physical look of vehicle, which can be evaluated under different lighting conditions to assess door gaps, feature lines, component interfaces, etc.

Figure 2: Example of a CNC milled function cube model of a vehicle.

❄️ Design Freeze

Once virtual and physical validation is complete, final CAD changes can be made, and the magical design freeze is reached. Design Release Engineers breathe a sigh of relief and hand-over, often several weeks later than intended, to Manufacturing or Supply Base Engineers to get all the bits manufactured, installed and bought-off for prototype and volume production.

There are imperfections with this process, namely being late changes, slippage in timing and the processes failing to acknowledge the to and fro between design and validation. But broadly these deficiencies were masked because all automakers were following variations of the same stage-gate process.

But this began to unravel when EV start-ups in the US and China applied lessons from the software and consumer electronics worlds which pushed speed and iteration over perfection.

⚡ What did EV Firms do differently?

While the established Stage-Gate process did ensure a robust product was released to the market, with steadily improving quality and safety with each iteration, it took approximately four years to progress from project Kick-Off to Launch.

EV firms and new automakers in Silicon Valley and China, while being unincumbered by legacy processes, had to learn how to build a vehicle from scratch.

Due to their proximity to the software and consumer electronics industry, they leant on these industries to guide their product development efforts.

🔁 Agility & Iteration

I remember my first months on a new project at Tesla back in 2014, where I had the expectation of attending multiple project reviews, reporting back progress against a predefined list of activities.

Instead, I was exposed to JIRA for the first time, where an ill-defined list of activities was bucketed together to be completed in a compressed timeline which bordered between aggressive and ridiculous.

It was my job to flesh out my own activities and work with other Design, Quality and Manufacturing functions to ensure the manufacturing process was planned out so that the product could be assembled within a given tolerance range, while maintaining the integrity of the product design.

This required developing multiple options, often involving design variations. However, with improvements in simulation software and compute power, selected options could be crash simulated and iterated for improvement.

While this was very rough initially, the process permitted learning, required cross-function communication via working meetings with engineers, and leveraged advances in virtual testing allowing for more iterations without the need for formal change requests.

In time, organizational memory grew so that interactions became more instinctive and through learning there was a clearer awareness of required deliverables, while still leaving room to explore new ideas.

This agility differs from the stage-gate system, prioritizing fast coordinated iteration cycles above pushing for a single perfect design release allowing issues to be discovered faster and permitting changes to be managed locally. This is especially critical when the product and production system is being debugged during manufacturing qualification and ramp.

🧩 The Power of Modularity

The speed of iteration in the design realm, along with multiple design updates, meant that EV entrants had to learn to apply the principle of modularity within manufacturing.

Just like in software, where code is broken into discrete functions that can be reused, swapped, or updated independently, allowing developers to improve or add isolated components while preserving the broader architecture, this modular mindset can be applied to hardware as well.

The first evidence of modular hardware in manufacturing was first seen on a large scale in consumer electronics, and is cascading into automotive production particularly in newer areas such as battery module assembly.

A modular manufacturing line is characterized by discrete, reconfigurable stations linked by robot or linear transfer systems, which enable flexibility in the face of inevitable design changes.

Without modularity, late-stage design modifications can render entire stations obsolete. Utilizing swappable fixtures, adjustable tooling, and standardized end-effectors enables changes to be accommodated quickly.

This flexibility protects capital investment, maintains product launch timing, and accelerates iteration, turning rigid production lines into adaptable platforms for continuous improvement.

♻️ Modularity: A Virtuous Cycle

The benefits of modularity have flowed back into the digital space with standardized components being designed that can quickly plug into a customized manufacturing equipment design.

This has allowed equipment vendors in China in conjunction with their high quantity of skilled labor to produce a fully detailed production line design in as little as 30 days, in comparison to the three to four months of traditional equipment vendors.

This time compression continues, where both standardized and custom components can be released to a dense network of suppliers that work from digital files, rather than 2D drawings to fulfill orders in short lead times.

The overall time compression has seen some automakers achieve product launches in two years, rather than the standard four.

🧠 First Principles over Established Processes

In my early experience as an apprentice, I saw how engineers responsible for commissioning production lines focused primarily on project management and sign-off criteria. The technical work of debugging, tuning and process optimization was largely left to the equipment vendor. At Tesla, Apple, and Rivian, my experience of this dynamic shifted significantly.

A lack of established standards and/or due to the novelty of the equipment meant that commissioning demanded a deep understanding of the manufacturing equipment itself. Engineers had to apply first principles thinking to troubleshoot in real time and pivot quickly as designs evolved.

For hardware disruptors, such as EV startups, it is necessary to cultivate this first principles thinking by hiring individuals who are capable of deconstructing complex problems to their fundamental components. This approach not only fosters quicker iteration cycles but also provides a source of learning and innovation.

With this hard-won knowledge, engineering teams are better equipped to scrutinize every part, process, and specification and apply the same thinking in the design phase to drive out unnecessary complexity in second-generation products.

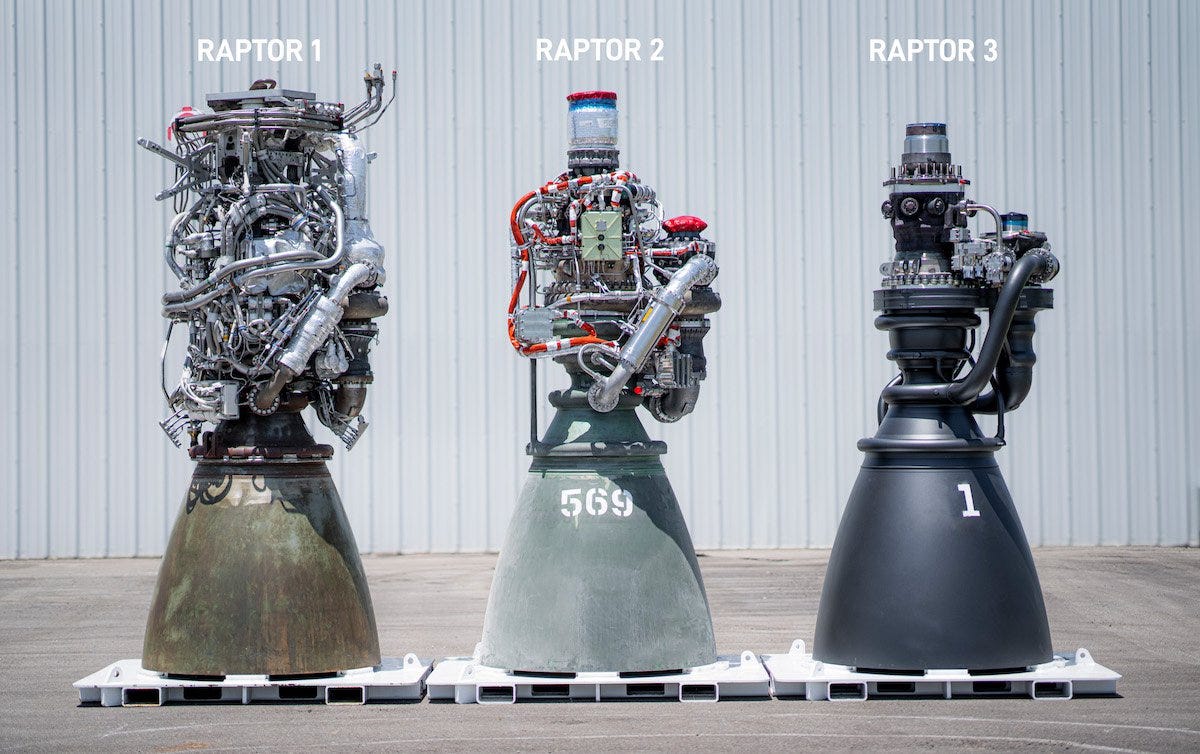

A good example is SpaceX’s evolution of the Raptor rocket engine, where learnings from the first generation led to a design evolution that became simpler with each iteration, shown in Figure 3.

Figure 3: Space-X Raptor Evolution Reducing Design & Manufacturing Complexity

🚀 Design is Never Done: Embracing the Iterative Edge

My experiences in automotive start-ups and consumer electronics companies have changed how I think about industrial product development. While traditional stage-gate processes brought consistency and accountability, they were designed for a slower era—one where designs could be locked down, changes minimized, and longer lead times tolerated.

But as technologies became more complex and timelines more compressed, rigid workflows begin to act as constraints rather than safeguards. Modularity, iterative development, and deep process understanding are essential ingredients for speed, resilience, and learning.

Ultimately, the goal should not be to reach a perfect design freeze, but to create a system that embraces controlled evolution. The most successful companies treat each product launch not as a fixed endpoint but as a launchpad for continual improvement, where every iteration sharpens the design, strengthens the process, and accelerates learning.

Whether developing rocket engines or electric vehicles, the ability to question assumptions, simplify intelligently, and adapt quickly will define the next era of hardware innovation.

Thanks for the feedback! Agree, rel and homologation can add to launch timelines, but maybe with increased confidence in virtual tools will mean that testing/certification of existing design can go on in parallel with the change process. We almost need something more fluid that phase gates, but a bit more coordinated that an entirely agile process - a middle ground is somewhere!

Great article, I’m also used to a phase gated approach with hard design freezes but have been thinking more about how to keep things fluid. Harder to do it in automotive than consumer electronics just due to safety and rel implications.